How to Start Your Small Business With an Engraving Machine? A Step-by-Step Guide

To start your small business with an engraving machine, first, research the market and identify your target audience. Then,

To start your small business with an engraving machine, first, research the market and identify your target audience. Then, invest in a high-quality engraving machine suitable for your needs.

Starting a small business with an engraving machine can be a profitable venture. Engraving machines offer versatility, allowing you to personalize a wide range of products. From customized gifts to industrial nameplates, the possibilities are endless. Begin by researching what products are in demand and who your potential customers are.

Invest in a reliable engraving machine that can handle various materials such as wood, metal, and glass. Focus on building a strong online presence and utilize social media to showcase your work. With dedication and strategic planning, your engraving business can thrive.

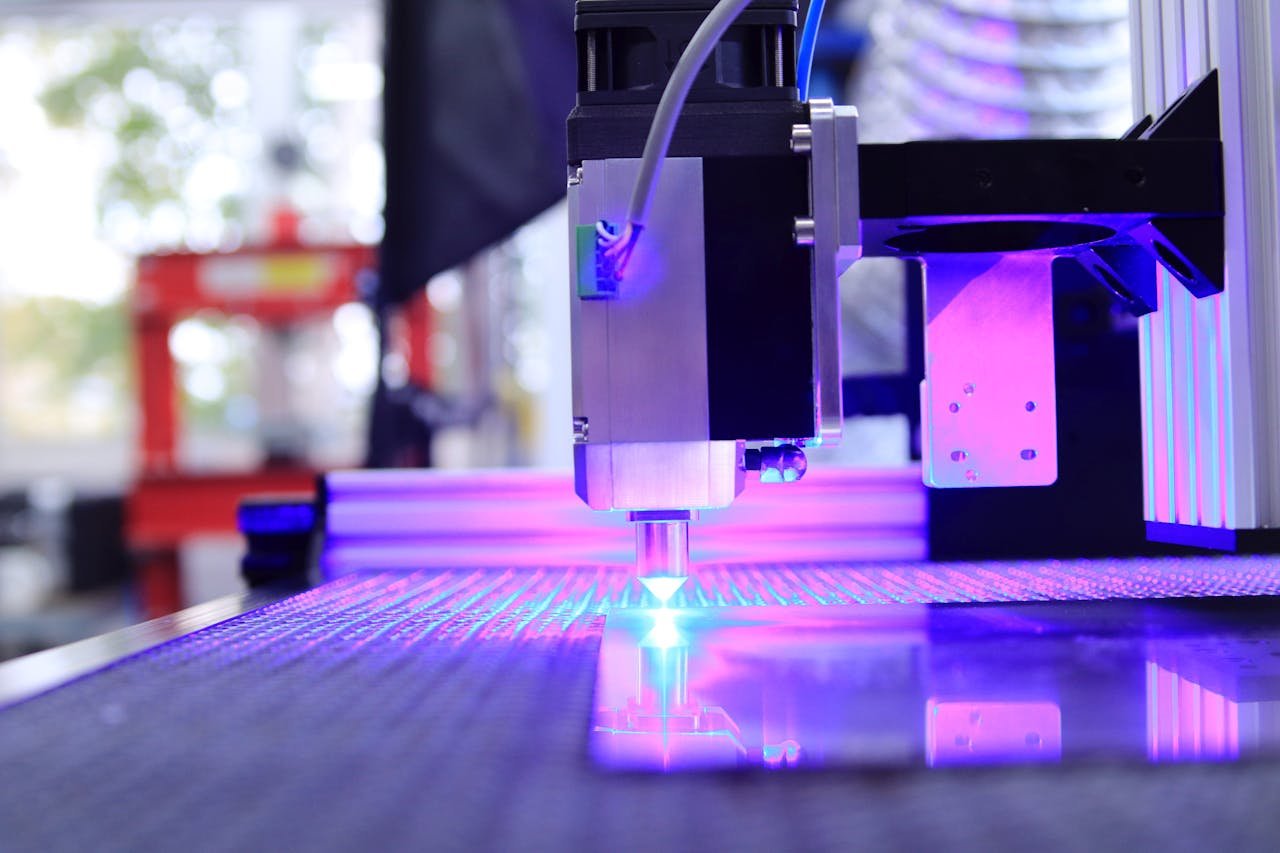

Choosing The Right Engraving Machine

Starting a small business with an engraving machine can be exciting. Choosing the right engraving machine is the first critical step. This decision will impact your business’s success. Here’s how to choose the right one.

Types Of Engraving Machines

There are various types of engraving machines. Each has its own benefits.

- Laser Engraving Machines: These use laser technology for precision. Ideal for detailed designs.

- Rotary Engraving Machines: Use a rotating tool. Best for deeper engravings.

- Dot Peen Engraving Machines: Use a pin to create dots. Good for metal items.

Factors To Consider

There are several factors to consider when choosing an engraving machine.

| Factor | Details |

|---|---|

| Material Compatibility | Ensure the machine works with your materials. Some machines handle metal better. Others work well with wood or plastic. |

| Precision | Precision is key for detailed work. Laser machines offer high precision. Rotary machines are less precise. |

| Cost | Consider your budget. Laser machines are more expensive. Rotary machines are more affordable. |

| Size | Think about the machine size. Smaller machines fit better in small spaces. Larger machines handle bigger projects. |

| Software Compatibility | Some machines need special software. Ensure it’s user-friendly and meets your needs. |

Choosing the right engraving machine involves understanding your needs. Consider the types and factors listed above. This will help you make an informed decision.

Setting Up Your Workspace

Starting a small business with an engraving machine is exciting. The first step is setting up your workspace. A well-organized workspace boosts productivity and safety. Let’s dive into the essentials for your engraving machine business.

Essential Tools And Equipment

Having the right tools and equipment is crucial. Below is a table with some essentials:

| Tool/Equipment | Purpose |

|---|---|

| Engraving Machine | The main tool for engraving items |

| Computer | For designing and controlling the machine |

| Design Software | To create and edit designs |

| Ventilation System | To remove dust and fumes |

| Work Table | A sturdy table for placing the machine |

Ensure you have these tools to start your business smoothly.

Safety Measures

Safety is key in any workspace. Follow these safety measures to protect yourself:

- Wear Safety Goggles: Protect your eyes from dust and debris.

- Use Ear Protection: Engraving machines can be loud.

- Ventilate Properly: Ensure good airflow to avoid inhaling harmful particles.

- Keep Workspace Clean: A clean space reduces the risk of accidents.

- Read Machine Manual: Understand your machine before use.

Adhering to these safety measures ensures a safe working environment.

Learning The Basics

Starting a small business with an engraving machine can be exciting. First, you need to learn the basics. This includes understanding how to operate the machine and knowing which materials to use. Mastering these basics ensures you create high-quality products for your customers.

Operating The Machine

Operating an engraving machine is easy. Begin by reading the user manual. It will guide you through the setup process. Make sure to calibrate the machine correctly. This ensures precise engravings.

Practice on scrap materials first. This helps you get a feel for the machine. Adjust the settings based on your material. Different materials require different settings.

Materials To Use

Choosing the right materials is crucial. Here are some common materials you can use:

- Wood: Popular and easy to engrave.

- Glass: Creates elegant designs but needs careful handling.

- Metal: Durable but requires more power.

- Plastic: Versatile and comes in many types.

Each material has its unique properties. Test different materials to find what works best for your products.

| Material | Difficulty Level |

|---|---|

| Wood | Easy |

| Glass | Medium |

| Metal | Hard |

| Plastic | Easy |

Creating Your First Engraving

Starting your small business with an engraving machine is exciting. The first step is creating your first engraving. This process includes designing your template and executing the engraving. Let’s break down these steps to make the process easier.

Designing Your Template

Designing your template is the first step. Use software like Adobe Illustrator or CorelDRAW. These programs help create precise designs. Ensure your design fits your engraving machine’s capabilities.

Here are some steps to follow:

- Choose a simple design for your first project.

- Use bold lines and clear shapes.

- Save your design in a compatible file format.

You can also use free design templates available online. These templates can save time and effort. Always double-check the size and dimensions of your design.

Executing The Engraving

Once your design is ready, it’s time to execute the engraving. Prepare your engraving machine by setting it up properly. Follow the manufacturer’s instructions carefully.

Here are some steps to follow:

- Place the material securely on the machine bed.

- Upload your design to the machine’s software.

- Adjust the settings for speed and depth.

- Start the engraving process and monitor closely.

Ensure you wear safety gear during this process. Protective glasses and gloves are essential. Keep a close eye on the machine to avoid errors.

Engraving takes patience and precision. Practice with simple designs first. As you gain experience, try more complex designs.

Marketing And Growing Your Business

Starting a small business with an engraving machine is exciting. But, marketing and growing your business is essential for success. This section will guide you through key strategies to help your business thrive.

Building An Online Presence

Creating a strong online presence is crucial. Start with a professional website. Make sure your website is user-friendly and mobile-responsive. Showcase your products with high-quality images and detailed descriptions.

Use SEO techniques to rank higher on search engines. Include relevant keywords like “engraving services” and “customized gifts”. Regularly update your website with new content.

Leverage social media platforms to reach a wider audience. Share your work on Facebook, Instagram, and Pinterest. Post engaging content, such as behind-the-scenes videos and customer testimonials. Encourage satisfied customers to leave reviews and share their purchases online.

Networking And Partnerships

Networking can open many doors for your business. Attend local business events and craft fairs. Meet potential customers and business partners. Always carry business cards to share with new contacts.

Form partnerships with local businesses. For example, partner with a wedding planner to offer custom engraved wedding favors. Collaborate with a local artist to create unique pieces.

Join online forums and groups related to engraving and small businesses. Participate in discussions and share your expertise. This builds your credibility and attracts new clients.

| Marketing Strategy | Action Steps |

|---|---|

| Online Presence | Create a professional website, use SEO, and leverage social media |

| Networking | Attend events, form partnerships, join online forums |

Frequently Asked Questions

Can You Make Money With An Engraving Machine?

Yes, you can make money with an engraving machine. Create custom products, gifts, and promotional items. Sell them online or locally.

How Do I Start An Engraving Business?

Start by researching the market and choosing your niche. Invest in quality engraving equipment. Create a business plan. Register your business and get necessary licenses. Promote your services through online marketing and local advertising.

How Much Do People Charge To Engrave?

Engraving costs vary by material and complexity. Prices typically range from $10 to $100 per item.

What Business Can I Start With A Laser Engraver?

You can start a personalized gifts business with a laser engraver. Engrave custom designs on wood, glass, metal, or leather. Offer products like plaques, jewelry, phone cases, and corporate awards. This business has high demand for unique and customized items.

Conclusion

Starting your small business with an engraving machine is a smart move. It offers customization and unique products. Follow the steps outlined to ensure success. Invest in quality equipment and practice your skills. With dedication and creativity, your small business can thrive and grow.

Embrace the journey and enjoy the rewards.